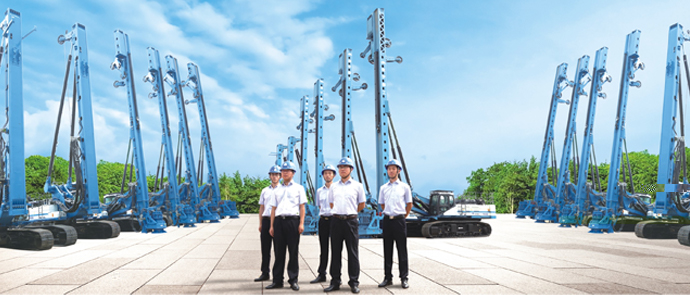

YTR230Dpro crawler-type rotary drilling rig is a small and medium rotary drilling rig developed by us for civil engineering, municipal construction, and railway, bridge pile foundation projects. It is widely used in the drilling operations of cast-in-place piles in soil, clay, pebble and mudstone beds, etc.

Equipped with imported genuine special chassis, Scania ECI engine with China’s Third Stage emission standard, strong power, energy saving and environmental protection.

Designed with high slewing brake torque and suitable for rotary drilling under heavy-duty and frequent-impact operating conditions.

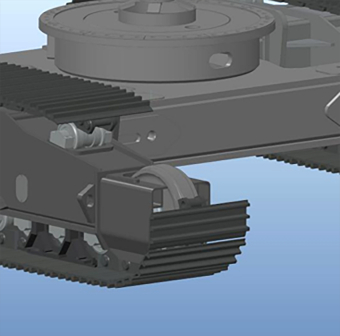

Features super spreading and super low center of gravity, provided with traveling mechanism made of super hard materials fitted with customized tensioner, with reasonable machining processes to ensure strong adaptation capacity, high reliability and stability of the traveling mechanism on site.

Before leaving the factory, each rotary drilling rig has been tested for 16 hours of sand test to test the technical parameters according to the test program.

The key structural components of the complete rig are analyzed for static, dynamic and fatigue performance with advanced design means, ensuring the reliability of the components.

Provided with lengthened and extra-strong power head fixing slot, reinforced box key force-bearing parts to extend the service life of the components under operating conditions with impact and vibration.

Designed with double-moving-arm parallel quadrangular derricking mechanism, providing good stability for operating conditions of rock penetration, with stronger resistance to vibration, impact, and torsion.

The mast is made of high-strength steel and constructed with box girder structure for light weight and high strength by optimizing the structure.

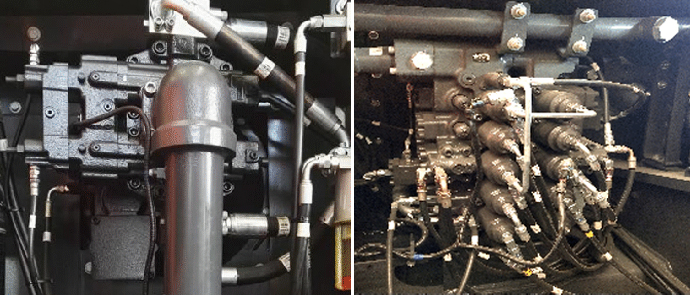

Provided with special integrated wiring harness, high-grade waterproof connectors to prevent poor contact under rainy weather conditions, reduce the failure rate, and improve the reliability of the electrical system.

Configured with a high-precision oil filtration system for Grade NAS8 cleanliness level of hydraulic oil, extending the service life of the hydraulic components.

The motor of power head winching reducer and the electro-hydraulic components come from internationally well-known brands.

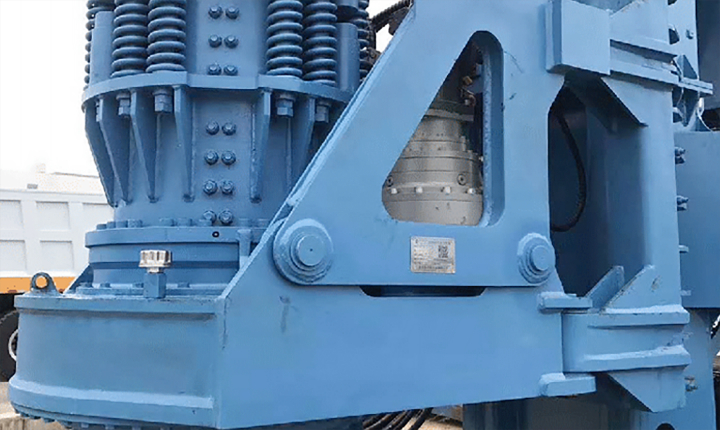

YTR230Dpro power head is configured with three motors, of which torque may be up to 246kN.m, and the rock penetration efficiency is increased by 18% (Rock penetration in Qingdao vs rock penetration in Malaysia).

With multi-body kinematics analysis and practical verification of the designed power head driving sleeve, it can ensure the best clearance between the drill rod fit, providing sufficient impact force for the soil throwing and earth impact, which greatly shortens the time of the earth impact, more suitable for clay layer, cement stratum.

Designed with standard mode and rock penetration mode, the handle is switched easily by pressing the pushbutton.

For the lifting and lowering function of the primary winch, the hydraulic confluence technology to double the lifting and lowering speed of the accessories for rotary drilling, greatly shorten the time of the inactive operation of the rotary drilling rig. The single-cycle operating efficiency is increased by 3%.

Optional secondary winch of impact

The secondary winch is designed with our matured free-falling reducer technology of dynamic compactor, provided with impact hammer to combine the percussion drilling and rotary and peeling construction of the rotary drilling rig.

The rock penetration efficiency increased by 10% and for function of wall compaction and protection.

The automatic rotation of the power head may reduce the operating labor intensity of operators so that the power head revolution is always under a high-efficiency state.

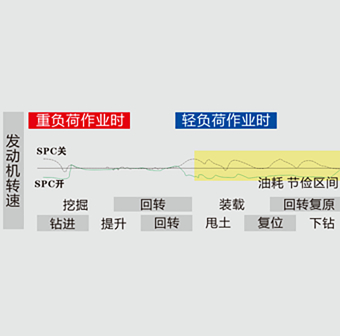

With Scania ECI engine and cutting-edge EPOS control system, different engine operating modes may be available. Fitted with SPC and other oil-saving control units, the engine, hydraulic system, and operating conditions can be matched each other by controlling the engine automatic idling speed and primary pump flow and with smart control the pressure of the hydraulic system, increasing the efficiency and reducing energy consumption. The oil consumption is reduced by 20% to 25% compared with equivalent products.

The mounting structure inside the power head box is optimized. The soil scraper is added. The service life of the oil seal is increased by 30%.

The inner key sleeved key bar is constructed with bolted wear-resisting steel plate for longer service life and lower repair cost.

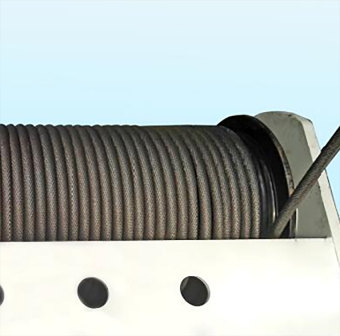

Equipped with lengthened and thickened drum for single-layer winding of steel wire rope, avoiding rope twisting, skipping or disorderly. Compacted strand rope may increase the service life of the steel wire rope by 20%.

The trolley wheel is equipped with high-rate pulley combination. The large diameter of the pulley and reversing and bending radius of the steel wire rope may increase the service life of the steel wire rope and pulley.

The service life of the special carrier roller structure is increased by more than 2 times.

The idler and rail protector mounting clearance, the fit clearance between the crawler holder and the base may be controlled, avoiding the derailing and chassis misalignment, extending the service life of the chain rail segment and supporting roller.

Operating cost control and monitoring: The latest real-time fuel consumption, operating hours and position may be provided for the equipment.

One-key appointment of services and the maintenance information twittered: Notification via short message service (SMS) on mobile phone for daily, weekly, monthly reports and, maintenance reminder, etc.

With our independently developed advanced controller programming system and combined with the latest control technology and hydraulic power transmission, various automatic control functions can be realized. Automatic mast lifting and lowering and automatic deviation correction of the mast; automatic earth impact, automatic rotation of the power head; limit load control of the engine and pump; automatic remote diagnosis of system troubles, etc.

The fuel may be fully automatically heated. The heater may be automatically switched on under cold weather condition.